Ever wondered what separates thriving businesses from those stuck in constant catch-up mode? The answer often lies in operational efficiency. It’s about creating a smooth, productive flow where every effort counts, leading to faster growth and stronger results. Let’s uncover what really makes operations efficient and what doesn’t.

What is Operational Efficiency?

Operational efficiency involves an organization performing its processes to provide goods and services at a low cost by optimizing resources, processes, and workflows. Operational efficiency is a metric that measures how well a business converts inputs (like labor, time, and materials) into outputs while minimizing waste, redundancies, and unnecessary costs. The aim is to achieve the maximum productivity at minimal spending to make assured, smooth, and streamlined operations in line with strategic goals.

Why Operational Efficiency Matters?

Operational efficiency is crucial for maximizing employee productivity, particularly in knowledge-based, service-oriented, or remote work environments. Streamlining processes, workflows, and tools helps focus the employees on more valuable tasks while reducing burnout and achieving such outcomes with less friction. Here are reasons why operational efficiency is important and how it affects companies on all levels.

1. Maximizes Productivity Without Overburdening Employees

Effective operations allow employees to concentrate on higher-value work rather than wasting time on repetitive processes. Automated routine work processes are there to increase productivity, thereby decreasing employee burnout and frustration. A systematic approach caters to collaboration, teams have open lines of communication with one another, avoiding any miscommunication and further working with greater efficiency on delivering projects more quickly due to a well-defined process with appropriate tool access.

2. Reduces Costs and Increases Profitability

Wasted resources, be it time, materials, or labor, translate into an extra cost, operational efficiency does not only reduce waste incurred but enables companies to maximally utilize inputs, and ultimately promotes profitability. This means lower operational costs enable more capital in innovation and growth. Cost efficiency also reduces financial risks when operations are streamlined through tools like source to pay software , companies gain better control over expenses, minimize budget overruns, and improve overall financial stability.

3. Strengthens Competitive Advantage

Businesses that are operating at higher efficiency will be ahead of those companies that are tied to traditional and sluggish processes in today’s demanding business world. Efficiency encourages a rapid response to customer needs, optimization of work, and reduction of operational risks. Well-optimized operations enable companies to scale faster, allowing them to expand without bottlenecks and ensuring sustainable, manageable growth while maintaining productivity.

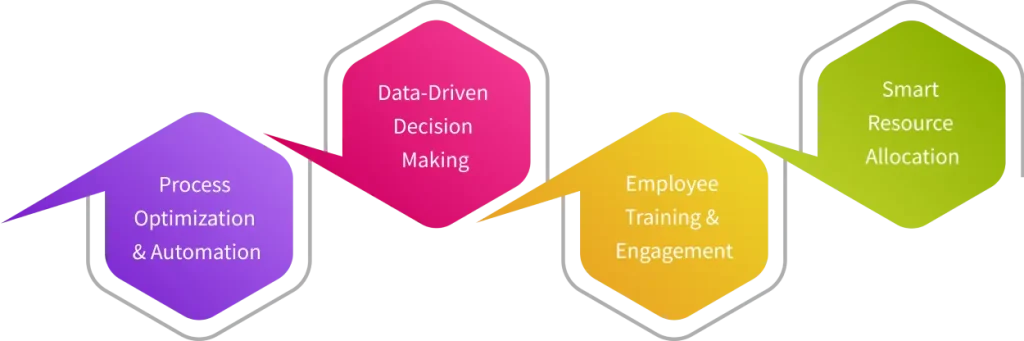

What Works: Proven Strategies for Operational Efficiency

Success in today’s fast-paced business world depends on operational efficiency. It’s not just about working harder, it’s about working smarter. By refining processes, leveraging data, empowering employees, and using resources wisely, companies can streamline operations and boost productivity. Here’s how:

1. Process Optimization & Automation

Every business has daily routines, but when approvals, data entry, and reporting begin to consume time and energy, they are doing their bit to sabotage productivity pursuit.

Process optimization is an art that involves analyzing workflows, identifying inefficiencies, and refining processes to eliminate unnecessary steps. Taking it a step further, automation uses advanced technology to manage repetitive tasks, reducing manual labor and minimizing costly errors. Solutions like IT asset management software help organizations streamline asset tracking, reduce administrative overhead, and boost operational efficiency by centralizing critical data in one place.

How it Works:

-

Carry out an audit of the business practices to analyze those areas where there is stagnation or unnecessary repetition of tasks.

-

Use workflow automation tools, such as project management software, CRM systems, and AI-driven assistants, to reduce manual effort.

-

Implement process standardization, so that people have less confusion when it comes to working together between departments.

-

Consistently monitor the performance and collect continuous employee feedback to create further improvements.

-

Train the teams to automate the tools efficiently, such as adjusting to the new changes and optimizing their work.

2. Data-Driven Decision Making

When businesses make decisions based on guesswork or assumptions then inefficiencies, opportunities and resources will be wasted. Data-driven decision-making provides a real insight for every choice which reduces risk and delivers better outcomes. Businesses can track their performance, predict future trends, and optimize their strategies through data collection analysis, and interpretation.

How it Works:

-

Collect sales reports along with customer feedback and employee performance metrics to gather necessary data.

-

Present complex information by using dashboards along with data visualization tools as a means to achieve clear and actionable results.

-

Implement predictive analytics to forecast market trends so that you can take advanced preventive action where issues might develop.

-

Encourage employees to build a data-driven culture when they utilize regular insights to enhance their work efficiency.

-

Key performance indicators (KPIs) need continuous measurement to track progress and enable essential changes to become effective.

3. Employee Training & Engagement

A company’s workforce is its greatest asset, but without proper training and motivation, employees can become disengaged, unproductive, or even resistant to change. Investing in the means of getting employees continuously trained and engaged ensures they readily contribute towards the achievement of the company’s objectives with zeal.

How it Works:

-

The organization needs to establish structured training systems that focus on specialized capabilities as well as interpersonal competencies.

-

Use interactive learning methods, such as workshops, e-learning platforms, and mentorship programs, to make training more engaging.

-

A culture of recognition should exist at work to appreciate employees for their valuable work contributions.

-

The workplace becomes more transparent when employees have the chance to provide feedback as well as express concerns and make workflow suggestions.

4. Smart Resource Allocation

Time, money, and talent are limited resources that make a big difference in a company’s efficiency, how they are distributed upstream is critical. Effective management of these valuable assets means that they are used to the greatest advantage, and more productivity is gained for the same amount of waste.

How it Works:

-

Identify high-priority tasks and allocate resources based on their potential impact.

-

Using workload management tools to make sure that tasks and activities are divided among employees and no task is left to a particular employee, especially to prevent burnout.

-

Implement budgeting strategies so that the funds are used in the right way in the right project and at the right time with no wastage of funds in the wrong areas.

-

Leverage outsourcing or automation for non-core tasks, allowing internal teams to focus on their strengths.

-

Continuously evaluate resource allocation and make adjustments based on performance data and business needs.

Struggling with operational bottlenecks?

Time Champ enhances efficiency and keeps work flowing.

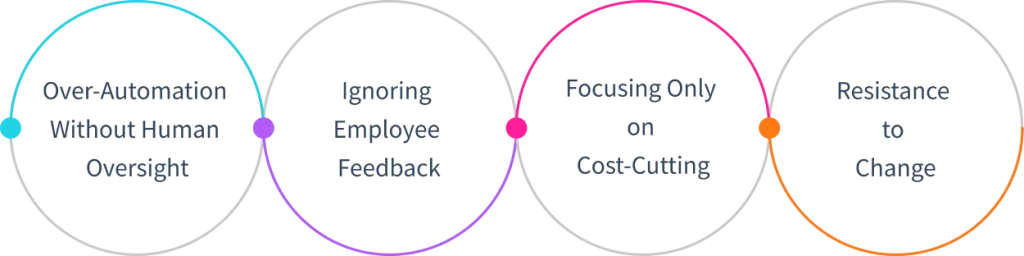

Signup for FreeBook DemoWhat Doesn’t Work: Common Pitfalls in Operational Efficiency

Achieving operational efficiency is not just about implementing new strategies, it’s also about avoiding mistakes that can slow progress and create new challenges. Most businesses are inadvertently entangled in the usual snares that deplete their progress. Below are some of the biggest blunders firms commit in an attempt to boost efficiency and how to avoid them.

1. Over-Automation Without Human Oversight

Automation can be transformational after efficiency, but an overreliance on technology in the business may lead to establishing inflexible systems with no room for change. Over-automation can lead to customer dissatisfaction, process failures, and even reputational damage when errors go unnoticed.

Potential Consequences:

-

Unforeseen issues might occur when automated systems are used because they often cannot handle exceptions which may lead to the customer’s concern being unresolved or incorrect data being processed.

-

With the shrinking of roles, employees become less engaged and there comes in lack of accountability and critical thinking.

-

Customers may become frustrated when they deal with unresponsive and unhelpful responses from robots that cannot understand the concerns of the customers.

-

When employees depend too heavily on systems, they lose the ability to innovate and problem-solve in advance of processes.

2. Ignoring Employee Feedback

Employees are the most important part of day-to-day operations, and they can bring issues of inefficiencies that might be missed by decision-makers. However, when companies ignore employee feedback, they risk creating a disengaged workforce, missing valuable opportunities for improvement, and fostering a culture of dissatisfaction.

Potential Consequences:

-

Employees may identify or feel that they have been devalued and are bound to experience a drop in morale and productivity.

-

Small operational inefficiencies may escalate into bigger concerns as a result of inadequate frontline understanding.

-

High employee turnover can result from frustration and the feeling that their voices don’t matter.

-

Company initiatives receive more resistance, as employees are less likely to endorse the changes, they did not have input into.

-

When employees stop sharing ideas because they feel that change is futile, stagnation will occur on the innovation platform.

3. Focusing Only on Cost-Cutting

Cutting costs is one of the most common reasons companies go into business. But when that’s the focus of efficiency efforts, companies can end up sacrificing quality, employee happiness, and sustainability in the long run. True efficiency is about creating more value, not cutting expenses.

Potential Consequences:

-

With a reduction in workforce or resources, employees get burnt out, morale goes down and overall performance also goes down.

-

Decisions on cost saving that compromise quality might damage the brand and the trust of the customer.

-

If critical investments in technology or training are neglected, they result in short-term savings costs which are long-term inefficiencies.

-

Failing to reinvest in innovation makes the company lose out to competition that focuses on long-term expansion.

4. Resistance to Change

Adaptability within an evolving environment of business is quite a necessity, yet many companies continue resisting change out of fear of uncertainty or a preference for old routines. This reluctance could lead to inefficiency, stagnation, and inability to espouse the book of opportunities.

Potential Consequences:

-

Outdated processes will continue to bog down the business and it will never be able to reach its full potential.

-

Frustration among the employees on the part of inefficient workflows may result in low levels of engagement and productivity.

-

The firm can struggle to compete against more agile companies that accept innovation and modernization.

-

A lack of change readiness makes other future transitions, including technological advances, more difficult and disruptive.

-

A culture of complacency is created when feeble resistance to improvement leads to acceptance of inefficiencies.

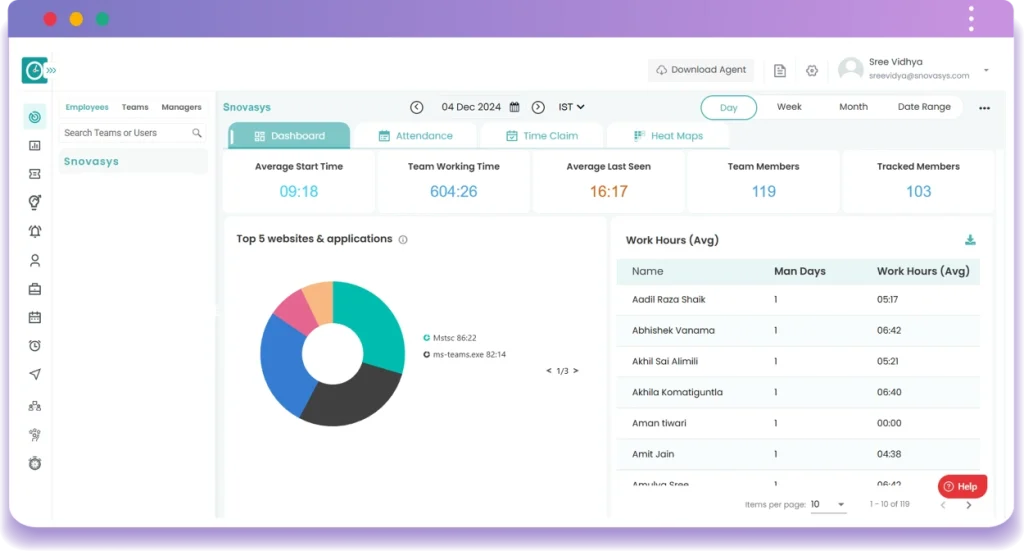

How Time Champ Can Improve Operational Efficiency

Operational efficiency is the backbone of any successful business, and Time Champ plays a crucial role in optimizing workflows, boosting productivity, and ensuring seamless execution of tasks. With Time Champ’s powerful features, you can optimize operations, eliminate waste and inefficiencies, and maximize output. Here is how Time Champ maximizes operational efficiency.

1. Real-Time Productivity Tracking for Smarter Workflows

Using Time Champ, managers can gain real-time insights into their employee’s activity as well as understand productivity trends and places of improvement. Examining work patterns will allow businesses to focus on task assignments, minimize wasted time, and make sure that teams keep their eyes on high-priority objectives. It also helps in detecting workflow bottlenecks early, allowing teams to make quick adjustments and maintain smooth operations.

2. Automated Time Management for Seamless Operations

Manual tracking and time logs can lead to errors and inefficiencies. Time Champ’s automated time tracking helps businesses obtain accurate work-hour records that assist in assigning the workload fairly and scheduling effectively. This brings about the elimination of unplanned delays, increases accountability, and ensures deadlines are met without overwhelming the employees.

3. Comprehensive Task & Project Management for Maximum Output

Keeping projects up to date is very critical for operational efficiency. Time Champ’s task and project management features allow teams to assign responsibilities, set deadlines, and monitor progress, all in one place. It helps create fewer confusions, more collaboration, and smoother running of project work without interruptions.

4. Attendance & Work Behavior Monitoring for Better Accountability

Manually tracking attendance and work habits is time-consuming and prone to human error. With Time Champ, you can automate attendance tracking and work behavior analysis to keep employees engaged and accountable. It provides a clear breakdown of productive and unproductive hours, helping managers assess efficiency levels and address potential distractions. Time Champ identifies trends like excessive idle time or overtime, managers can implement necessary adjustments to maintain productivity and ensure a balanced workload.

Conclusion

In conclusion, operational efficiency is key to business success. By refining processes and avoiding common pitfalls, companies can eliminate waste, boost performance, and foster a more productive work environment. Balancing innovation with oversight will enable businesses to attain long-term success as well as overcome challenges efficiently.

Boost your team’s efficiency with Time Champ

Get started today and watch productivity soar!

Signup for FreeBook DemoFrequently Asked Questions

Operational efficiency and productivity are closely knit terms working together, not identical. The output created in a particular setting from a unit of input is the definition of productivity, whereas operational efficiency is how to streamline processes by minimizing different wastes to gain the best possible output in the least amount of time.

The performance indicators in the form of production output, cycle time, resource utilization, and cost per unit can help in measuring the operational effectiveness of a business. Tracking customer satisfaction levels can also reveal how well processes meet expectations. Regular internal audits provide insights into bottlenecks and areas for improvement.

Operational efficiency focuses on doing things right (with minimal waste), while operational effectiveness is about doing the right things to achieve business goals. Efficiency works with the optimization of resources, while effectiveness works toward ending the movements of these resources with respect to the outcome. A business may be efficient without being effective; it can achieve some results, but they do not align with the strategic objectives to be achieved.